Unlocking Innovation with High Temp Solutions in Art Supplies, Product Design, and 3D Printing

In the rapidly evolving landscape of modern manufacturing, art, and technology, the term high temp has become a cornerstone for innovation and excellence. Whether it’s creating stunning works of art, designing cutting-edge products, or advancing 3D printing technologies, harnessing high temp capabilities unlocks a new realm of possibilities. At arti90.com, we specialize in providing top-tier high temp solutions tailored to meet the demanding needs of artists, designers, engineers, and creators.

Understanding the Power of High Temp Technology

High temp technology refers to the use of materials, tools, and processes capable of withstanding, generating, or operating at elevated temperatures. This capability is essential for applications that require durability, precision, and resilience under extreme conditions.

- Thermal Resistance: Components or materials that maintain integrity in high-temperature environments.

- Enhanced Durability: Tools that withstand wear and tear during intensive use.

- Advanced Material Compatibility: The ability to work with specialized high-temp materials like ceramics, refractory metals, or specialty polymers.

- Precision Manufacturing: Maintaining accuracy at elevated temperatures common in processes like soldering, casting, or additive manufacturing.

Innovative Applications of High Temp in Art Supplies

For artists, mastering the use of high temp art supplies opens new avenues for creative expression. From firing ceramics to working with heat-resistant paints, high temperature methods have become essential in the arts industry.

High-Temperature Ceramic and Glass Art

The development of high temp ceramics and glass materials allows artists to create durable, vibrant, and intricate pieces. Techniques such as kiln firing and glass blowing require precise temperature control, often exceeding 1200°C, to achieve desirable textures and color effects.

Heat-Resistant Colors and Coatings

Specialized high temp paints and coatings enable artworks to withstand heat exposure without fading or degradation. These materials are perfect for kinetic sculptures, outdoor installations, and functional art pieces exposed to sunlight or high temperatures.

Advanced Tools for Ceramic and Metalworking

- High temp kilns: Essential for firing ceramics and glass artworks at consistent high temperatures.

- Heat-resistant gloves and tools: Allow safe handling of hot materials during creation and finishing processes.

Revolutionizing Product Design with High Temp Materials and Processes

In product design, integrating high temp capabilities ensures products can meet demanding specifications related to heat resistance, structural integrity, and longevity. This is particularly relevant for industries such as aerospace, automotive, and consumer electronics.

Designing with High Temp Materials

Utilizing materials like titanium alloys, ceramic composites, and refractory metals, designers can develop products that perform reliably under extreme thermal conditions, such as engines, turbines, and high-performance electronic devices.

Prototyping and Manufacturing

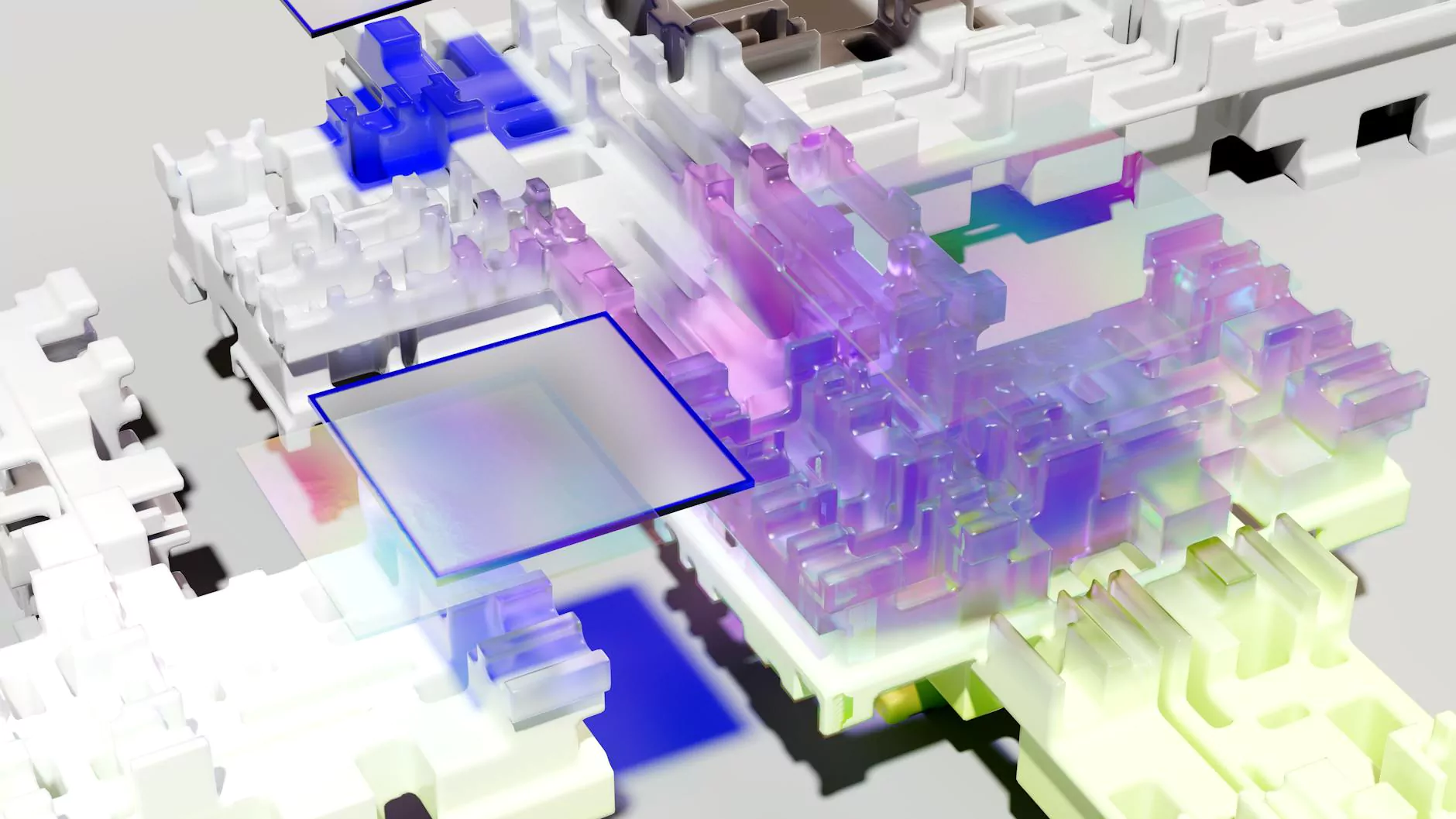

3D printing with high temp filaments and powders allows rapid prototyping of parts that can endure extreme environments. Technologies like selective laser sintering (SLS) and fused deposition modeling (FDM) with specialized filaments enable the creation of durable prototypes for testing in real-world high-temperature scenarios.

Thermal Management and Advanced Coatings

- Heat-resistant coatings: Protect sensitive components and extend product lifespan.

- Thermal insulation: Critical in designing energy-efficient systems.

Transforming 3D Printing with High Temp Technologies

3D printing is rapidly evolving with high temp capabilities, leading to breakthroughs in complex manufacturing, precise tooling, and custom parts. Using high temp 3D printing filaments and powders, manufacturers can produce parts that withstand extreme conditions where traditional plastics would fail.

High Temp 3D Printing Filaments and Powders

- Poly Ether Ether Ketone (PEEK): A high-performance thermoplastic that offers exceptional strength and heat resistance, suitable for aerospace and medical applications.

- Ultem (PEI): Known for its high strength-to-weight ratio and high temp resistance, used for functional prototypes and end-use parts.

- Refractory ceramics and composites: Enable the creation of parts for high-temperature environments, such as furnaces and exhaust systems.

Benefits of High Temp 3D Printing

- Durability: Parts can tolerate up to 260°C or higher, fitting demanding industrial applications.

- Complex Geometries: Enables the production of intricate designs that traditional manufacturing might find challenging.

- Cost-Effective: Reduces lead time and manufacturing costs compared to traditional machining and casting.

Advantages of Incorporating High Temp Solutions at arti90.com

Choosing the right high temp materials and tools can significantly impact the quality, durability, and performance of art projects, products, and printed parts. At arti90.com, our focus is to deliver premium high temp solutions that meet the highest standards.

"Our commitment to excellence in high temp materials and processes ensures that our clients are equipped with the best tools for their most challenging projects."

Why Choose arti90.com for High Temp Needs?

- Expertise: Extensive knowledge in art supplies, product design, and 3D printing with high temp materials.

- Quality Assurance: Only sourcing and providing durable, proven high-temp materials compatible with various industries.

- Customization: Tailored solutions to meet specific temperature and performance requirements.

- Innovation: Cutting-edge offerings to keep your projects ahead of the curve.

- Support: Dedicated customer service to guide you through selection, application, and optimal results.

Future Trends in High Temp Technologies

The future of high temp technology is promising, with innovations such as nanomaterials, advanced ceramics, and composite systems pushing the boundaries of what’s possible. Emerging fields like additive manufacturing will continue to leverage high-temp processes to create smarter, more resilient, and sustainable solutions.

Emerging Trends Include:

- Nanostructured High Temp Materials: Enhanced strength and thermal management capabilities.

- Smart Coatings: Adaptive coatings that respond to temperature changes for improved performance.

- Hybrid Manufacturing Techniques: Combining traditional methods with high temp 3D printing to optimize results.

Conclusion: Embracing the Power of High Temp for Innovation and Excellence

Harnessing the potential of high temp technologies elevates art, product design, and manufacturing to new heights of creativity, durability, and performance. By integrating high temp materials and solutions, innovators can build stronger, more resilient, and visually stunning creations capable of withstanding the rigors of extreme environments.

At arti90.com, we are dedicated to providing industry-leading high temp products and expertise to empower your projects and bring your visions to life. The future belongs to those who dare to innovate — and with high temp solutions, that future is already here.