Unveiling the Excellence of Business in Metal Fabrication: Your Guide to Leading Mold Maker China

In an era where precision engineering and innovative manufacturing dominate the industrial landscape, the metal fabrication sector stands as a cornerstone for numerous sectors including automotive, aerospace, consumer electronics, and industrial machinery. Among the myriad of skilled players in this domain, mold maker China emerges as a pivotal force, delivering high-quality, cost-effective solutions that empower businesses to accelerate product development and maintain competitive edges.

Understanding the Significance of Metal Fabrication in Modern Business

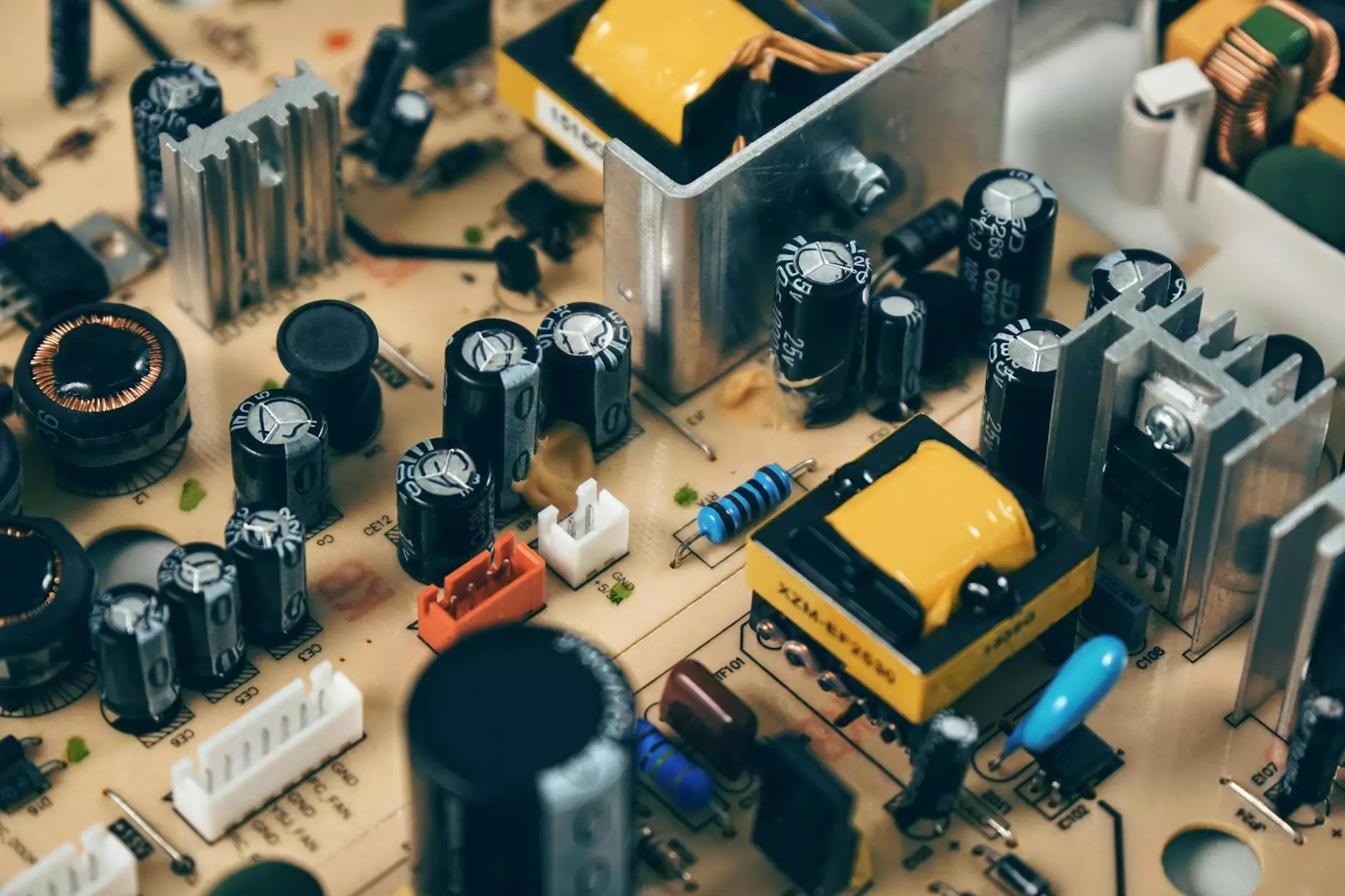

Metal fabrication encompasses the creation of metal structures through cutting, bending, assembling, and finishing techniques. This process is fundamental to creating everything from simple components to complex assemblies. Businesses invested in this industry understand that precision, durability, and efficiency are non-negotiable qualities for sustaining success.

Leading metal fabricators leverage cutting-edge technology, skilled craftsmanship, and innovative processes to meet the extraordinary demands of modern markets. They inspire confidence and trust within their client relationships, fostering growth and competitive resilience.

The Strategic Role of 'Mold Maker China' in Global Manufacturing

China has long been recognized as a manufacturing powerhouse, especially renowned for its mold maker capabilities. The term mold maker China signifies not just a geographic location but a commitment to innovation, quality, and cost leadership in the domain of specialized tooling and mold production.

Companies worldwide depend on Chinese mold makers for diverse reasons:

- Cost Efficiency: Lower labor and material costs translate into significantly reduced manufacturing expenses.

- High-Quality Standards: The best mold maker China companies adhere to strict quality controls, certifications, and standards such as ISO, ensuring durable and precise molds.

- Advanced Technologies: Integration of CNC machining, EDM, and other innovations enhances mold precision and manufacturing speed.

- Mass Production Capabilities: The scale of manufacturing in China allows for quick turnaround times, vital for meeting tight project schedules.

How DeepMould.net Reinforces Its Leadership in the Metal Fabrication Industry

Among the prominent names shaping the future of metal fabrication and mold making in China, deepmould.net stands out as a top-tier enterprise committed to delivering excellence, innovation, and customer satisfaction.

DeepMould.net exemplifies what it means to be a true metal fabricator in China, offering end-to-end solutions that span from initial concept design to mass production. Their expertise extends across various industries, including automotive, consumer electronics, industrial machinery, and more.

Comprehensive Capabilities of DeepMould.net in Mold Manufacturing

Design and Engineering Excellence

DeepMould.net employs a team of highly skilled engineers who leverage CAD/CAM software to create precision molds tailored to client specifications. Emphasis is placed on designing for manufacturability, minimizing production costs, and optimizing mold durability.

State-of-the-Art Manufacturing Facilities

The company invests in advanced manufacturing facilities equipped with CNC machines, laser cutting, EDM, and polishing equipment to ensure each mold meets the most exacting standards of quality and precision.

Quality Assurance and Certification

Rigorous quality control procedures are integrated throughout all stages of production. Certifications such as ISO 9001:2015 ensure that every mold and component adheres to international standards, promoting reliability and longevity for end products.

Rapid Prototyping and Low-Volume Production

DeepMould.net offers rapid prototyping services, allowing clients to test and refine designs quickly. Their flexibility in low-volume production is ideal for startups and companies needing specialized molds for niche markets.

The Competitive Advantages of Partnering with DeepMould.net

- Cost Effectiveness: Competitive pricing without compromising quality, leveraging China’s manufacturing scale.

- Customization and Flexibility: Tailored solutions to meet unique project demands and specifications.

- Timely Delivery: Efficient project management ensures on-time completion, minimizing downtime.

- Technical Support: Expert consultation services help clients choose the best materials and designs for their needs.

- After-sales Service: Ongoing support ensures long-term satisfaction and performance of molds.

The Top Industries Benefiting from High-Quality Molds in China

Automotive Industry

From vehicle body parts to intricate interior components, the automotive sector demands durable molds capable of supporting high-volume production runs with tight tolerances.

Consumer Electronics

The rapid evolution of electronic devices calls for precise molds that can efficiently produce complex, miniaturized components for smartphones, wearables, and home appliances.

Aerospace and Defense

High standards for safety, precision, and reliability make aerospace components requiring specialized molds an essential aspect of this industry’s manufacturing process.

Industrial Machinery

Heavy-duty molds used in the production of industrial equipment must withstand repetitive stress and harsh operating conditions, demanding top-tier craftsmanship and materials.

Innovations in Mold Making: Embracing the Future with Technology

The field of mold maker China is continually advancing through:

- Automation: Integrating robotic systems for increased precision and reduced human error.

- Smart Manufacturing: Utilizing IoT and data analytics to monitor process quality and improve efficiency.

- Material Advancements: Employing high-performance steels and composites for molds, extending lifespan, and improving product quality.

- 3D Printing: Combining additive manufacturing with traditional methods to accelerate prototyping and produce complex mold components.

Strategic Tips for Succeeding in the Metal Fabrication and Mold Making Business

If you aim to deepen your footprint or start a venture within this industry, consider the following:

- Invest in Quality Control: Ensure all stages of production follow strict guidelines to prevent costly defects.

- Leverage Technology: Stay updated with the latest manufacturing software and machinery to stay competitive.

- Build Strong Relationships: Foster trust with reliable Chinese mold maker companies like deepmould.net for long-term collaboration.

- Focus on Sustainability: Implement environmentally friendly practices and materials to meet global standards and enhance brand reputation.

- Diversify Your Portfolio: Offer various services, including design, prototyping, and volume production, to satisfy different client needs.

Conclusion: Partnering for Success in Metal Fabrication and Mold Maker China

In today's competitive global economy, the success of your business in metal fabrication depends heavily on partnering with trusted, innovative, and efficient manufacturers. DeepMould.net exemplifies excellence in the field of mold maker China, providing high-quality solutions aligned with international standards. Embracing advanced technology, maintaining strict quality controls, and fostering strategic collaborations are the drivers that can propel your business to new heights in this thriving industry.

By choosing a reputable partner like DeepMould.net, you gain a competitive edge, reduce costs, and ensure the delivery of superior products. The future of metal fabrication in China holds immense potential, and with the right approach, your business can capitalize on these opportunities to expand and innovate globally.