3D Printing in Road Cleaning Equipment: Revolutionizing Efficiency and Performance

The Power of 3D Printing

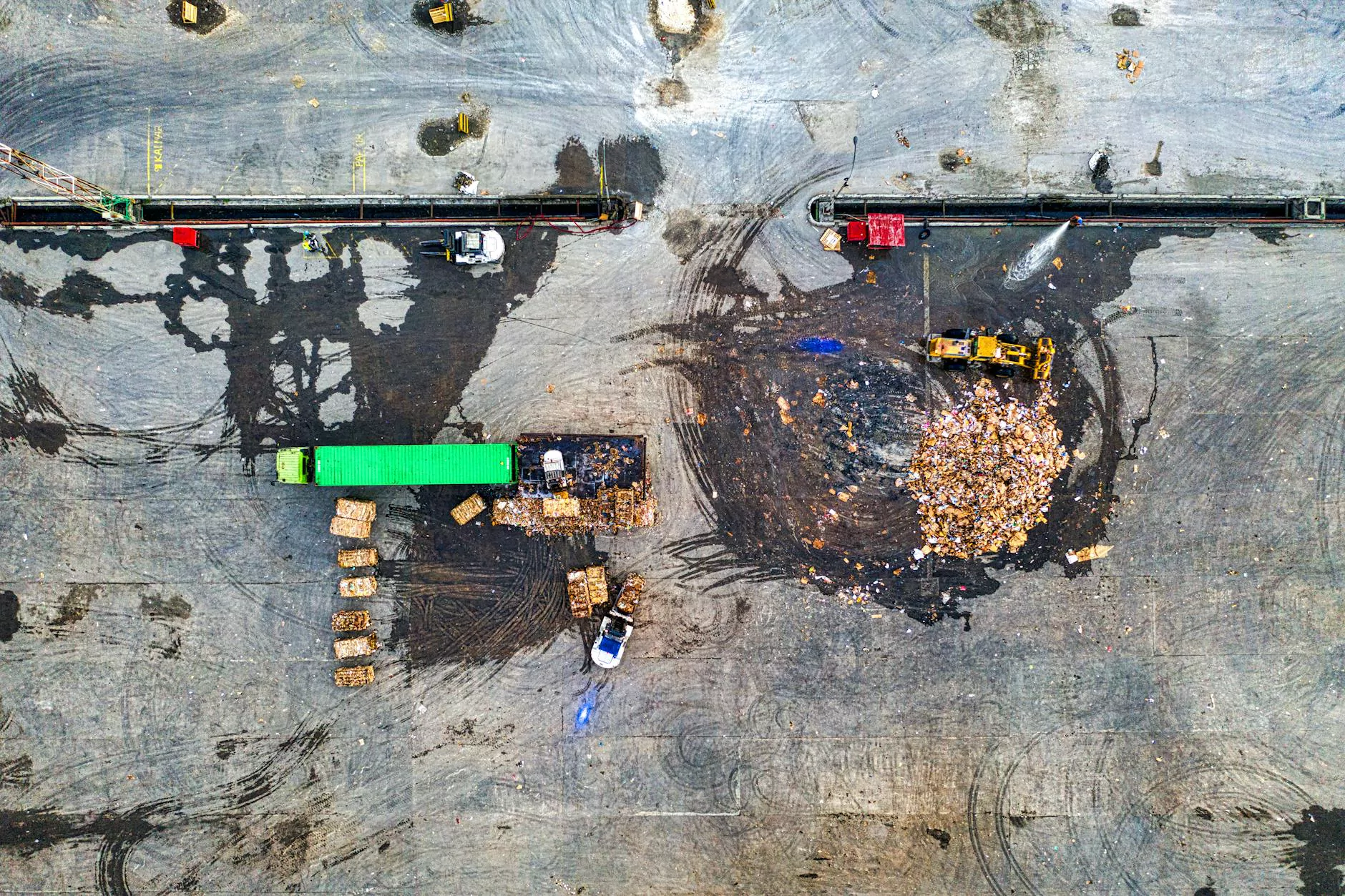

When it comes to road cleaning equipment, one name stands out: Ceksan Sweepers. With their dedication to innovation and cutting-edge technology, Ceksan Sweepers has embraced the power of 3D printing in revolutionizing the efficiency and performance of their sweepers. By incorporating this innovative approach, Ceksan Sweepers has set a new industry standard for cleaner and safer roads.

Enhancing Efficiency

Efficiency is a crucial factor in road cleaning equipment, and Ceksan Sweepers understands this better than anyone. With the integration of 3D printing technology, they have taken efficiency to a whole new level. By utilizing this advanced manufacturing technique, Ceksan Sweepers can produce complex and intricate parts with precision and speed.

Traditional manufacturing methods often involve multiple steps, increased costs, and longer production times. However, with 3D printing, Ceksan Sweepers can streamline the manufacturing process, saving both time and money. This, in turn, allows them to deliver their road cleaning equipment to customers in a more timely manner, ensuring quick and efficient services to municipalities and road maintenance agencies.

Unparalleled Performance

Performance is the key factor that sets Ceksan Sweepers apart from the competition. The integration of 3D printing technology enhances the performance of their road cleaning equipment in numerous ways. One significant advantage is the ability to create customized parts that perfectly fit the unique needs of each sweeper machine.

With 3D printing, Ceksan Sweepers can easily optimize the design of their equipment, ensuring maximum efficiency and functionality. The ability to create intricate geometries and lightweight structures allows for improved weight distribution, reduced fuel consumption, and increased maneuverability.

Quality and Durability

One common concern with new technologies is the quality and durability they offer. However, Ceksan Sweepers guarantees the highest standards in their road cleaning equipment. Each part produced with 3D printing undergoes rigorous testing and quality control measures to ensure optimal performance and longevity.

By utilizing high-quality materials and advanced printing techniques, Ceksan Sweepers can create parts that are not only durable but also resistant to wear and tear. This means their road cleaning equipment can withstand the harsh conditions of daily use, providing reliable and consistent performance year after year.

Environmental Benefits

In addition to the numerous advantages mentioned above, the integration of 3D printing technology in road cleaning equipment brings significant environmental benefits. Ceksan Sweepers, driven by their commitment to sustainable practices, embraces this technology to reduce waste and minimize their carbon footprint.

With traditional manufacturing methods, excess materials often end up as waste. However, 3D printing ensures that only the necessary amount of material is used, reducing waste generation. Additionally, the ability to create complex and lightweight designs with fewer components means less energy consumption during operation.

Conclusion

As road maintenance becomes an increasingly important aspect of urban development, the role of efficient and reliable road cleaning equipment cannot be overstated. Ceksan Sweepers, with their dedication to innovation and forward-thinking practices, leads the industry with their integration of 3D printing technology.

By continuously pushing the boundaries of what is possible, Ceksan Sweepers ensures cleaner and safer roads for communities worldwide. The efficiency, performance, and environmental benefits achieved through 3D printing make their road cleaning equipment truly exceptional.